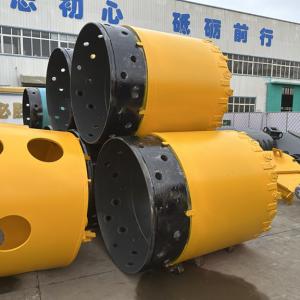

Stop end element and extractor

- Product Item : DC-stop end

- Category: Diaphragm Wall Grab & tools

- Width Range: 500,600,800,1000,1200mm etc

- Application: Diaphragm wall project

- Length: 3m-10m

- Color: Customized

Diaphragm wall stop-end elements are temporary formwork, usually made of steel, used to create watertight, well-defined vertical joints between adjacent concrete panels in a diaphragm wall (slurry wall) construction, ensuring structural integrity and preventing water leakage by using specialized couplings (like bayonet couplings) and rubber seals (water stops) that get embedded or removed to form the joint profile.

How They Work

- Installation: The stop-end elements are assembled and lowered into the excavated slurry trench before concrete placement.

- Excavation: The trench for the adjacent panel is excavated, supported by slurry, with the stop-end elements defining the panel edge.

- Concreting: Concrete is poured (often using the tremie method), displacing the slurry.

- Extraction: After the concrete hardens, the stop-end elements are extracted, leaving behind a perfect, watertight joint for the next panel to connect to, or sometimes remaining as a permanent feature, as in the Milan Joint system where a PVC pipe is broken open to allow concrete penetration.

INQUIRY

CATEGORIES

LATEST NEWS

CONTACT US

Name: Sales Manager

Mobile:+8615111295229

Tel:+8615111295229

Whatsapp:008615111295229

Email:info@drillcan.com

Add:No.118, Xiongtian Road, Changsha, Hunan, China