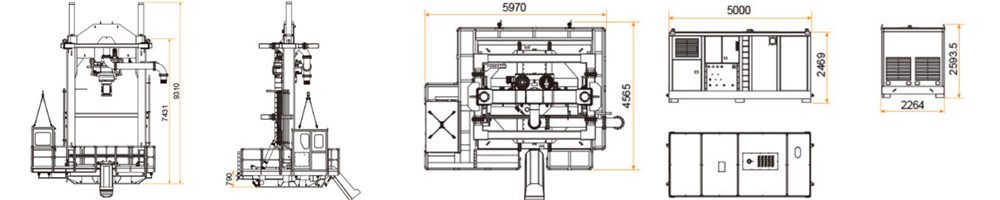

Reverse Circulation Drilling Machine RCD JRD200

- Product Item : JRD200

- Category: Reverse Circulation Drilling Machine(RCD Rig)

- Max. Diameter: 2000mm

- Application: Large diameter drilling

- Warranty: One year

- Color: Customized

Application:

Reverse Circulation Drilling Machine is suitable for large diameter,ultra-deep or rock-socked pile and other complex geological conditions of drilling construction. it is widely used in drilling pile foundation of land large buildings, harbor, wharf, embankment protection, bridge, offshore wind power station and so on. it is an altemative product of other pile equipment.

Features:

1.Full hydraulic power head,largetorque,suitable for variousstratigraphic environments,especially for hard rock and other strataconstruction.

2.Full hydraulic stepless speed regulation, according to the workingconditions to adjust the pump and motor displacement, match the constantpower hydraulic pump and diesel engine output power, make full use of thediesel engine performance, save fuel.

3.Using high-power diesel engine, suitable for field and offshore no-power-supply construction.

4.Tiltable gantry frame and power head,compactstructureeasy-disassemble drilling pipe and bit, safe and reliable.

5.Color LED controller, monitor the working status of diesel engine and whole system, safe and intuitive.

6.Modular structure,convenient disassembly and transportation.

7.High strength operation room, protect the safety of operator.

8.Various working modes, such as automatic drilling, constant pressuredrilling and manual drilling.Suitable for construction under variouscomplicated geological conditions.

Parameter:

JRD200

JRD300

Max. drilling diameter

2000mm

Max. drilling diameter

3000mm

Engine rating

260kw

Engine rating

272kw

Total weight

22t

Total weight

37t

Down force of Cylinder

680kN

Down force of Cylinder

1130kN

Lifting force of Clinder

1110kN

Lifting force of Clinder

1840kN

Max. speed of Power head

33rpm

Max. speed of Power head

23rpm

Max. speed torque

100kN/m

Max. speed torque

145kN/m

Min. speed of Power head

0-9rpm

Min. speed of Power head

10rpm

Min. speed torque

200kN/m

Min. speed torque

200kN/m

Factory Views:

1. Customized drill pipe automatic welding robot.

2. Drill pipe shall be preheated before weldingand insulated after welding to ensure reliable.

3. Sealing test of finished drill pipe to ensure the quality of drill pipe.

Drilling Tools:

Cases:

INQUIRY

CATEGORIES

LATEST NEWS

CONTACT US

Name: Sales Manager

Mobile:+8615111295229

Tel:+8615111295229

Whatsapp:008615111295229

Email:info@drillcan.com

Add:No.118, Xiongtian Road, Changsha, Hunan, China