Company news

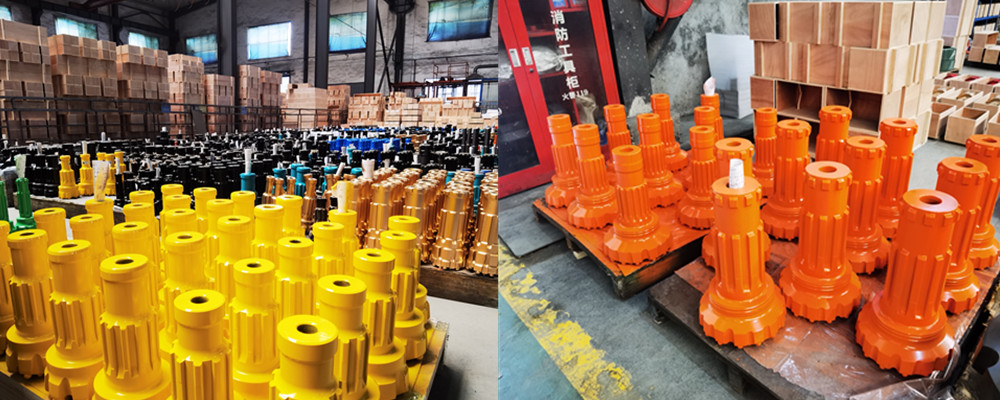

DTH drill bit packing and shipping

DTH drill bits are integral to the DTH drilling method, where the hammer mechanism is positioned directly behind the bit within the borehole. The hammer delivers percussive blows to the bit, which then breaks up the rock or other material through a combination of impact and rotation. This process allows for efficient drilling of boreholes, even in hard rock formations.

Key Features:

Tungsten Carbide Buttons: The buttons on the bit's face are made of extremely hard and durable tungsten carbide, providing the necessary wear resistance for breaking down tough materials.

Various Designs: DTH bits come in different face designs (e.g., convex, concave, flat) to suit various ground conditions and drilling requirements.

Size and Shape: They are available in a range of sizes and shapes to accommodate different borehole diameters and drilling applications.

Connection: The bit is connected to the drill string, which transmits rotation and impact force from the drilling machine to the bit.

DTH drilling is widely used in mining, construction, and infrastructure projects.

It's particularly useful for drilling blast holes in quarries, creating foundation holes for buildings, and drilling for geothermal energy or water wells.

CATEGORIES

LATEST NEWS

CONTACT US

Name: Sales Manager

Mobile:+8615111295229

Tel:+8615111295229

Whatsapp:008615111295229

Email:info@drillcan.com

Add:No.118, Xiongtian Road, Changsha, Hunan, China